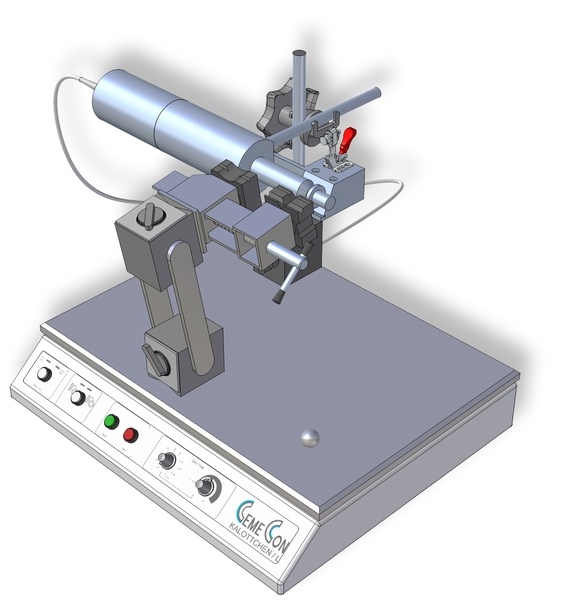

The calotte grinder Calotte L

In the production and development of thin coatings with PVD technology (Physical Vapor Deposition), the determination of the coating thickness is one of the most important measurement methods.

The calotte grinder Calotte L:

The calotte grinder Calotte L:

- is used to determine coating thicknesses and coating rates

- uses a broad projection of the layer thickness, which can also be measured with low magnification (Vmin =50)

- measures layer thicknesses between 0.1 and 30 µm

Item no.: 33401

Customs tariff no.: 84799070

Properties:

To grind the layer, a hardened steel ball is rotated on the coated substrate surface. Since many coatings are harder than the steel ball used, diamond suspension is additionally introduced between the coating and the steel ball via a pipette.

With calotte grinding unit, CemeCon offers the possibility of meeting the diverse applications in coating production and evaluation. The "Kalottchen L" calotte grinding device is ideally suited for fast and simple layer thickness determination of PVD layers.

Scope of delivery:

With calotte grinding unit, CemeCon offers the possibility of meeting the diverse applications in coating production and evaluation. The "Kalottchen L" calotte grinding device is ideally suited for fast and simple layer thickness determination of PVD layers.

Scope of delivery:

- Calotte L Calotte Grinder

- Diamond suspension for calottes

- Ball ø 20.0mm / Class 3

- Quick clamping fixture for standard measuring pins

- Clamping jaw fixture for parts up to 50mm width/diameter

- Magnetic holder for flat parts made of steel (e.g. saw blades)

- Clamping plate 300 x 400mm for variable measurement setup

- Precision spindle bearing with 80 mm projection

- Analog and discrete timer function 5 seconds to 3 minutes

- change of direction of rotation