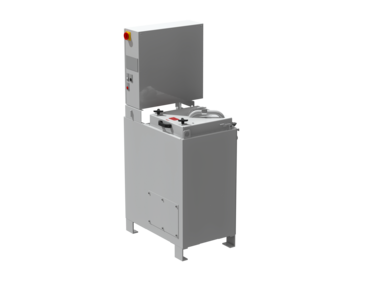

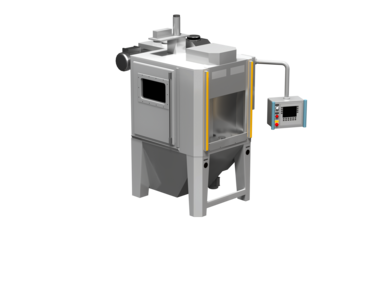

CC800®HiPIMS

The CC800® HiPIMS is capable of producing all existing CemeCon coatings and almost all PVD coatings available on the market. With coating rates up to 2 μm/h HiPIMS and coating thicknesses from 1 µm to currently 12 µm. With a filling level of up to 1800 rotary tools or 5000 indexable inserts. It is the fastest, most flexible and most economical production system on the market and is the perfect platform for developing customised processes. Tool manufacturers can use this to differentiate their products in the market and achieve a competitive advantage.

Item no.: 800-MLHIPIMSC2

Customs tariff no.: 84798997

References